Swiss Automation, Inc. is a leader in precision machining. We utilize the latest technology in multi-axis CNC Swiss Screw machines, enabling us to service our customers with speed, quality, and precision. Swiss Automation, Inc. is one of the largest manufacturers of Precision Turned Components in the US, with over 150 of the finest dual-spindle lathes in the world, many with up to 12 axis of cutting capability. We are one of the country’s largest holders of both Citizen and Tornos-Bechler DECO CNC Swiss-Type Screw Machines in addition to a wide array of Star, Miyano, Hardinge, and Eurotech machines.

This technology allows our customers to design complexity into their product features because we have the technology to support their specifications. Our “state of the art” equipment allows us to:

- Produce complex parts in one operation, saving time and money

- Produce components with tolerances to .0002″

- Machine parts up to 2.75″ diameter

- Reduce set-up time and quickly change over the machines to new jobs

- Serve you with accuracy, precision and short lead times

Swiss Automation, Inc. is ISO 9001:2015 and ISO 13485:2016 Certified. Our Quality Assurance and Customer Service Programs are comprehensive. Customer needs are handled with care and efficiency, from quoting through final inspection.

Swiss Automation, Inc. proudly serves the Medical, Aerospace / Defense & Electrical, and Hydraulics / Pneumatic Industries.

Come Build Your Future at Swiss Automation!

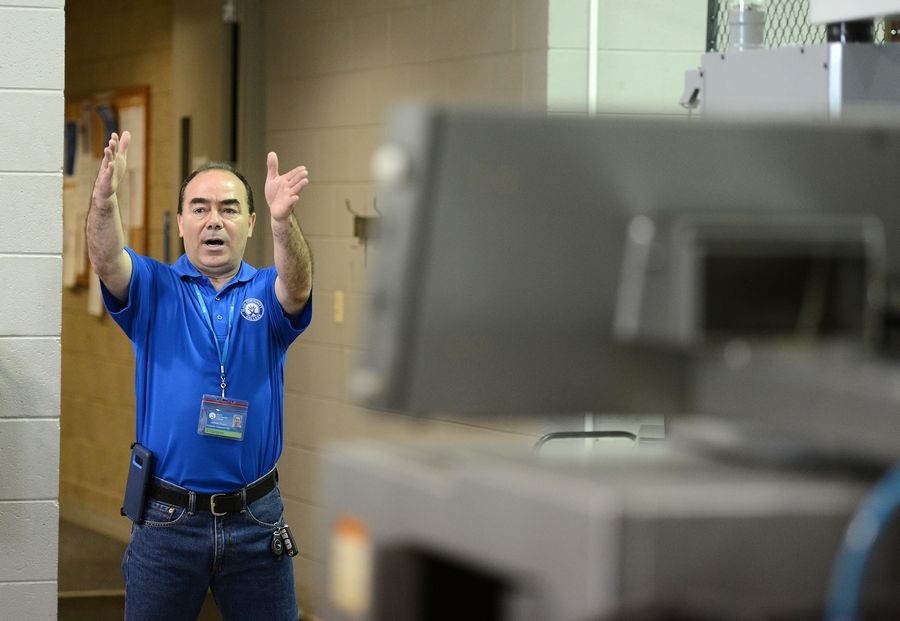

Swiss Automation is extremely proud to have recently received a certificate from the Department of Labor for our newly “Registered Apprenticeship Program”. While Swiss Automation has had a well-developed apprenticeship program in place for years, this new certification provides national recognition for building a quality training program and a fabulous career pathway for Swiss CNC Operators. We are developing great talent and helping to bridge the manufacturing skills gap in the US.

Registered Apprenticeship Programs (RAPs) are made up of 5 components.

- Business Involvement

- On-the-Job Training

- Related Training Instruction

- Wage increases for skills gained

- Nationally Recognized Credential

Apprentices that participate and graduate from this program will receive a nationally recognized credential awarded by the Department of Labor acknowledging their competency and skill set.

Partnerships with the Technology and Manufacturing Association (TMA) and the Lake County Workforce have made this program possible.

We’ve been sending selected apprentices to the TMA for the additional training and have received grants through Lake County Workforce for the cost of the training.

More than anything, this recognition speaks to the quality Swiss Automation prides itself on. The quality of the parts we manufacture is only as good as the operators that we train. We have achieved the gold standard in training with this apprenticeship!

Swiss Automation continues to grow.

Our 20,000 sq ft addition is coming along smoothly! Swiss Automation will have room for up to 60 more pieces of equipment in June of 2019, bringing us to a total of 150,000 sq ft. We are busy dedicating equipment for 24/7 production with both our large and small partners. Lead times will be down to 2 to 4 weeks!

Barrington manufacturer donates $1.3 million in gear, training to ECC.

Check out the newest article on Swiss Automation from the Chicago Tribune.

We continue to donate equipment, software, and expertise to our community partners in education. There are tons of opportunities for new generations of technical experts. We are always hiring! These are great, and interesting careers working with innovative technology to build incredible products for Aerospace and Defense, Medical Devices, Hydraulics, Firearms and many other applications. American Manufacturing at its very best! Build your future at Swiss Automation!